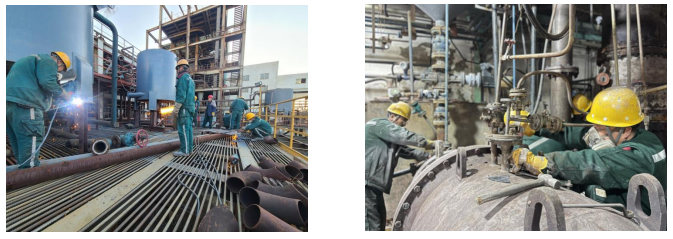

March 5th, 2024 15:00,Boiling chlorination 4 # line 1 # chlorination furnace has ended its historical operation cycle, shut down and started the chlorination furnace maintenance plan. Due to the long operation cycle, the overhaul of the fluidized bed chlorination furnace has added many difficulties to its own cleaning and overhaul work. However, through the leadership of the production center planning and careful organization in advance, the production coordination department makes full efforts to rush to repair, the equipment engineering department closely cooperates, the safety and environmental protection department escorts, and the four departments work together seamlessly. Relying on the spirit of unity and Mount Taishan moving, the overhaul startup time has been reduced by 44%, creating the best in history, and winning precious time for completing the annual output target.

Before the maintenance and start-up plan, the production center closely monitored the operation status of the 1 # chlorination furnace on the boiling chlorination 4 # line, planned and deployed in advance, and organized the management personnel of the second workshop to formulate a shutdown and start-up plan on February 18th. On February 19th, the equipment engineering department discussed and confirmed the formulated plan, and completed the implementation of the maintenance plan with the production coordination department before February 23rd.

During this maintenance process,management areas are divided according to responsibilities,and zoom in on every detail, implement specific work to everyone, providing strong support for the progress and quality control of maintenance and start-up.Adopting dual line operation of boiling chlorination furnace(On the basis of keeping the original personnel unchanged), the heating time of the 2 # chlorination furnace is reasonably formulated according to the operating status of the 1 # chlorination furnace. During the heating stage of the 2 # chlorination furnace, a dedicated person is on duty 24 hours a day to improve the maintenance progress and quality in the most effective, time-saving, and economical way.Implement morning and evening summary reports,Maintenance personnel system, plan implementation system, daily development of maintenance task plan and completion on the same day.

The Production Coordination Department focuses on the overall service of the center to ensure emergency repairs,guarding the original intention with ingenuity, fully carrying forward the "Forrest Gump spirit", facing the characteristics of tight time, heavy tasks, and multiple cross operations, systematic planning, layer by layer linkage, and practical training of the team to do a good job in supporting the production system, completed all the maintenance work of the 4 # boiling production line in just 8 days.

Establish a youth assault team in the maintenance workshop,Throughout the entire maintenance cycle, all personnel were on duty, adhering to the concept of "high-quality and efficient maintenance", once again setting a record for the shortest maintenance cycle of the boiling line.The instrument workshop always maintains a style of "fast, stable, meticulous, and practical",thoroughly deployed, compressed the planned 6-day maintenance task into 4 days, continuously prepared for 72 hours without interruption, and completed over 100 tasks including instrument wiring, replacement, and debugging. Complete each maintenance step with high quality.

Equipment Engineering Department intervenes in advance,Organize the production center to conduct a joint site survey with the construction unit, and based on production needs and actual site conditions, scientifically and reasonably develop an outsourced construction plan. According to the project schedule milestones, reverse the project schedule, and require the construction unit to organize equipment prefabrication in advance and prepare for the pre construction of the project.

Adopting a project responsibility system,Decompose the construction goals and tasks in a targeted manner, assign responsibilities to individuals, implement them effectively, and ensure seamless connection with the construction unit, thereby improving the efficiency of construction management work.Deeply coordinate on-site construction,On March 11th, 9 subcontracted construction tasks were completed ahead of schedule, including the repair of the chlorination tail gas rinsing tower, replacement of the tail gas pipeline, sealing of the chlorination furnace manhole, and replacement of the oxidized toluene storage tank.

The Ministry of Safety and Environmental Protection strengthens the safety supervision and management of maintenance work sites,arrange dedicated safety and environmental protection management personnel to conduct safety and environmental protection inspections on various operations at the maintenance site, with a focus on checking the implementation of safety and environmental protection measures and violations of rules and regulations, strictly preventing the occurrence of "three violations" during the maintenance period, and ensuring safety and stability during the maintenance period.

Safety management personnel strictly implement the 5-minute on-site work requirement,Before signing the special work permit, a safety inspection was conducted on the maintenance site to confirm the hazardous characteristics of the operation, personnel's wearing of labor protection, provision of fire emergency equipment, safety technical disclosure before the operation, and implementation of safety measures. This effectively controlled the safety risks of various maintenance operations and provided reliable guarantees for the smooth completion of various maintenance tasks.

The successful completion of the furnace maintenance and start-up work has gathered the wisdom and sweat of all employees in the production center, production coordination department, equipment engineering department, and safety and environmental protection department. With the spirit of overcoming difficulties and the courage to break the wrist, they have demonstrated the excellent quality and style of CITIC Titanium Industry, taking practical actions to shoulder heavy burdens and overcome difficulties, and making new contributions to the comprehensive completion of annual goals and tasks.

Production Center

2024.3.15

Return

Return